Ensuring clean, dry compressed air is crucial for the efficient performance and longevity of equipment in commercial settings. Air dryers play a vital role in maintaining air quality within compressed air systems. Whether you operate a manufacturing facility, automotive workshop, or food processing unit, installing an air dryer enhances productivity and reduces operational risks.

Why Air Dryers Are Essential in Commercial Setups

Compressed air often contains moisture. When air is compressed, the moisture content condenses into liquid water, which can lead to equipment damage, pipeline corrosion, and compromised product quality. Air dryers eliminate this moisture, ensuring that only clean, dry air flows through the system. Key benefits include:

- Prevents Corrosion

Moisture leads to rust and degradation of tools and equipment. Air dryers protect against long-term damage and wear. - Enhances Efficiency

Excess moisture can freeze or clog lines, reducing the efficiency of compressed air systems. Dry air ensures smoother operations. - Preserves Product Quality

In industries such as pharmaceuticals, food and beverage, and electronics, even slight contamination from moisture can affect the end product. Air dryers help maintain strict quality standards. - Reduces Maintenance Costs

Equipment exposed to moisture usually requires more frequent maintenance. Air dryers help reduce service needs and associated costs.

Types of Air Dryers for Commercial Applications

Selecting the right air dryer is essential for reliable and consistent performance. Different dryer types serve different needs:

- Refrigerated Air Dryers

Ideal for general-purpose use, these dryers cool compressed air so that moisture condenses and can be separated. They are best for environments where a dew point between 3°C and 10°C is sufficient. - Membrane Air Dryers

These compact dryers use membrane technology to selectively remove water vapor. They are suitable for smaller applications or where energy efficiency is a priority. - Desiccant Air Dryers

These systems use a desiccant material to absorb moisture and are best for industries that require ultra-dry air, with dew points as low as -40°C. They are widely used in the medical, pharmaceutical, and electronics fields. - Deliquescent Air Dryers

These cost-effective and simple systems use hygroscopic materials to absorb moisture. They are effective but require frequent replacement of the drying agent.

Best Practices for Air Dryer Installation

Correct installation is essential for maximizing performance and efficiency. Consider the following:

- Assess Your Air Needs

Determine the volume of air your system handles and the level of dryness required. Critical applications demand higher air purity. - Allow Sufficient Space

Make sure there is enough space around the air dryer for proper ventilation and easy maintenance access. Overcrowded setups can lead to overheating and inefficiencies. - Install in the Correct Position

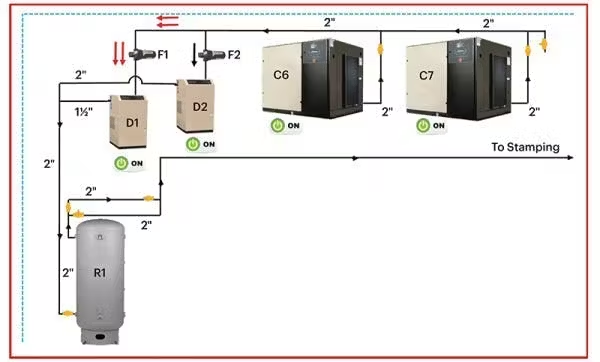

Place the dryer downstream of the compressor but before air reaches end-use equipment. This ensures moisture is removed before distribution. - Provide Proper Drainage

As air dryers extract moisture, an effective drainage solution must be in place. Many models include automatic drains, but some may require a dedicated line. - Use Proper Piping and Fittings

Match the piping to the dryer’s connections and check for airtight seals. Leaks can lead to energy loss and reduced performance. - Maintain Regularly

Establish a routine maintenance schedule to inspect filters, drain systems, and desiccant media (if applicable). Timely maintenance extends equipment life and ensures peak efficiency.

Why Choose Chicago Pneumatic?

Chicago Pneumatic offers high-performance air dryers, compressors, and air treatment solutions tailored to various commercial and industrial needs. Their equipment is built to deliver consistent results with minimal downtime, backed by a legacy of engineering excellence.

Conclusion

Air dryers are essential for keeping commercial air compression systems efficient and reliable. They protect equipment, maintain product quality, and help reduce operating costs. By choosing the right type of air dryer and ensuring proper installation and upkeep, businesses can significantly enhance performance and minimize risks.